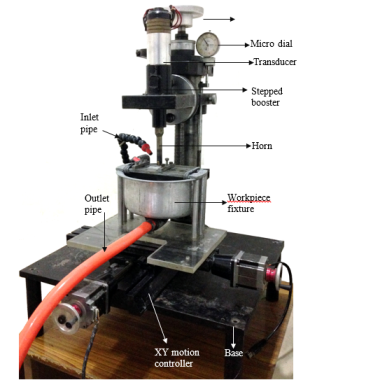

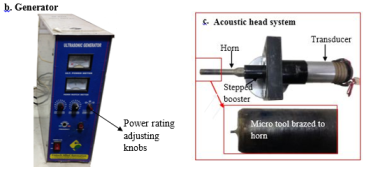

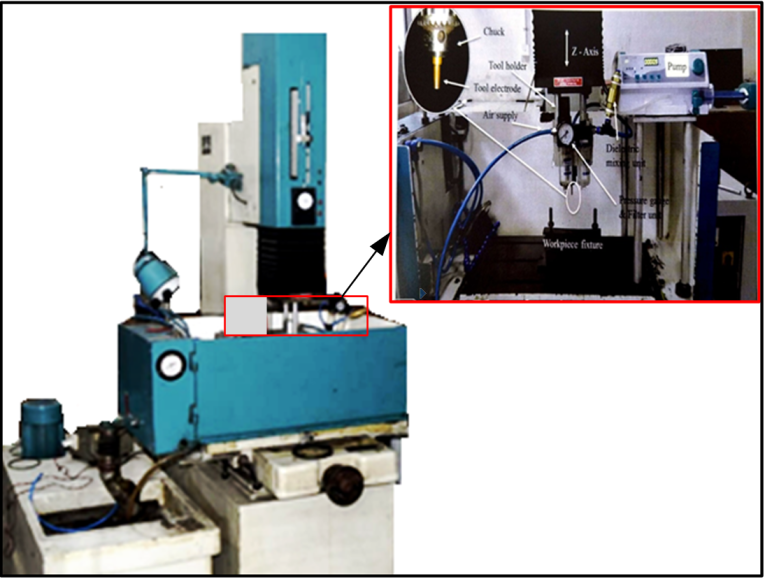

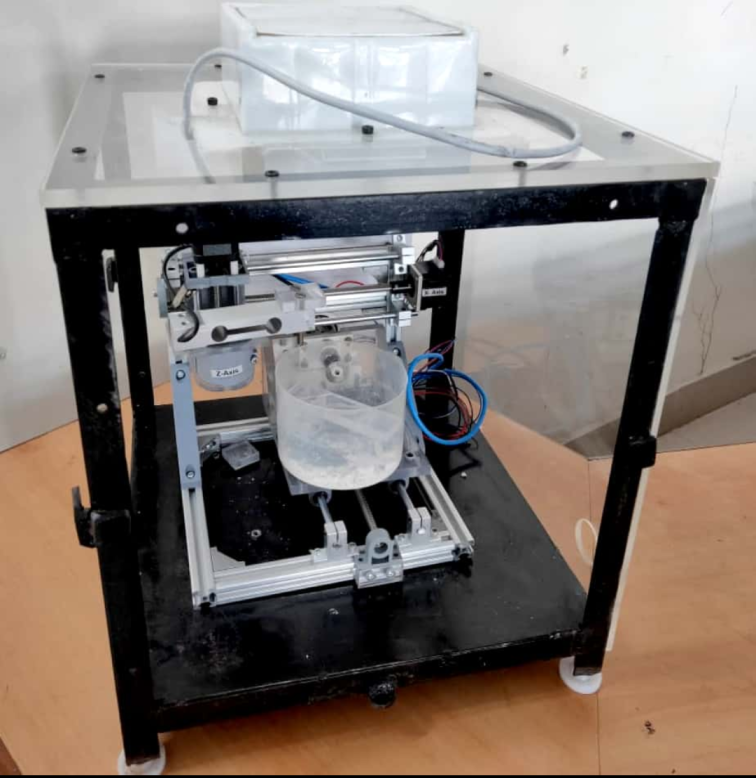

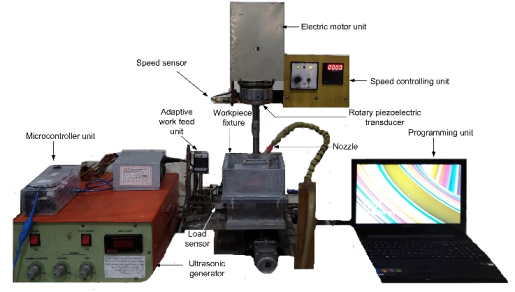

Development of adaptive feedback controlled electric hydro dissection device

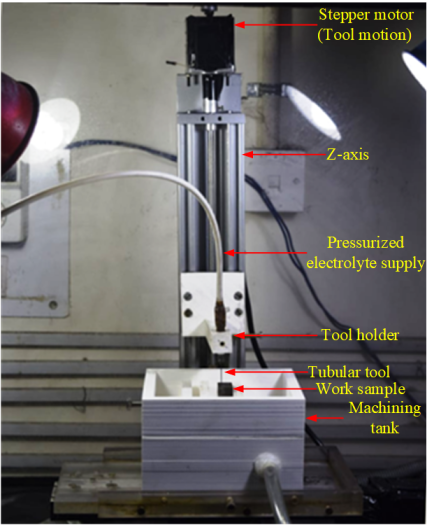

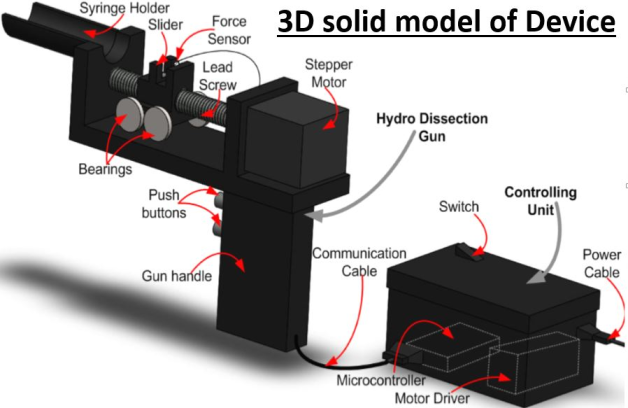

A hydro dissection device with feedback control facility was developed, which can be used for cleft lip and palate surgery. This innovative device provides smooth and controlled injection. Also, the device has special feature of monitoring and recording live data during the surgical procedure.

Team Members:

• Mr. Rajendra Kumar Arya

• Prof. Akshay Dvivedi

Nominated as best amongst all the innovations from the IIT Roorkee for the year 2019.

Nominated for the 100 best innovations by the Indian Innovators Association Award.

The Adaptive Feedback Controlled Electric Hydro-Dissection Device was Showcase Exhibit at the “World Conference on Access to Medical Products”, organized by the Ministry of Health and Family Welfare, GOI and WHO.