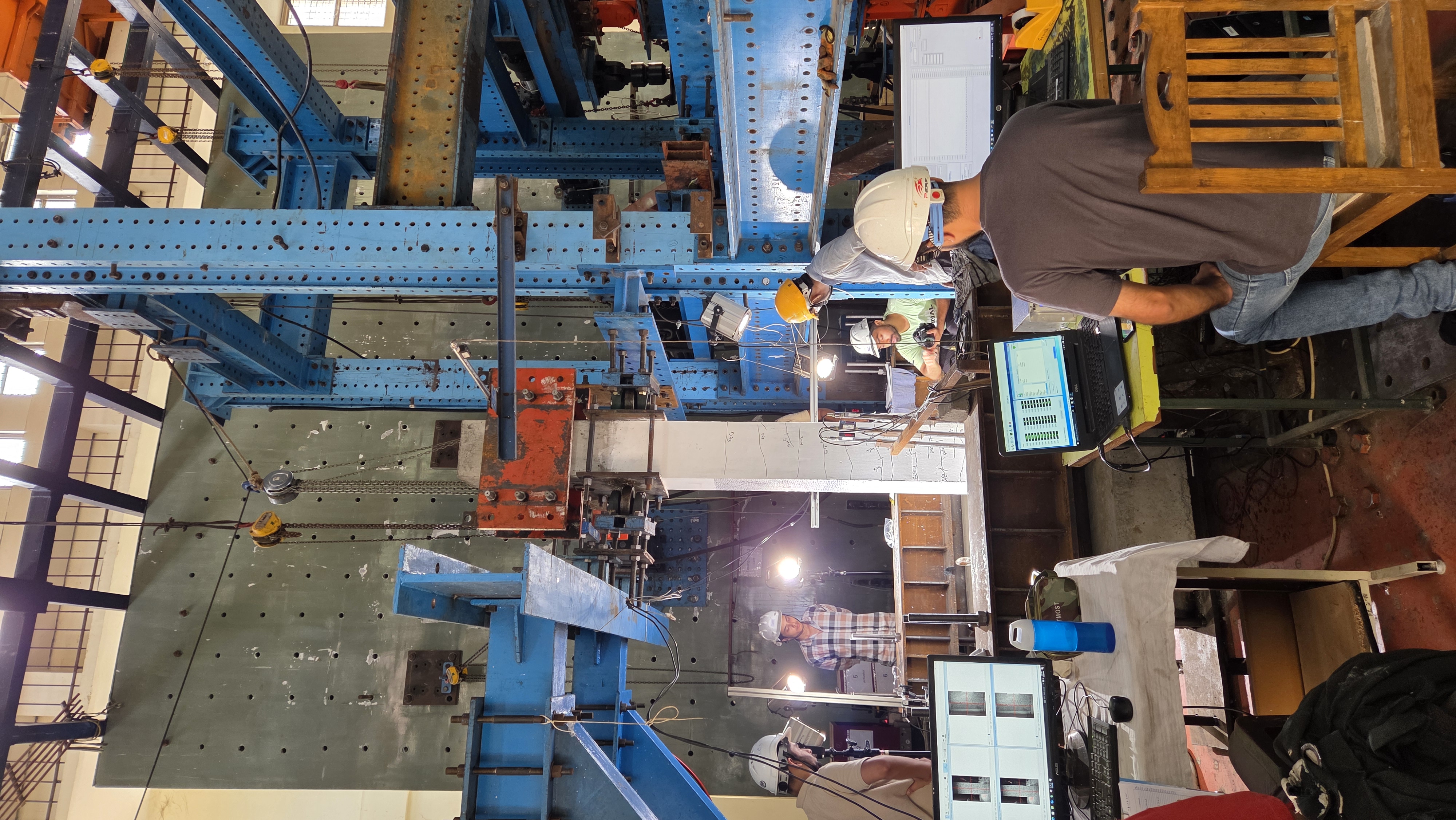

In-plane cyclic load test on full scale 2-storey H-wall constructed with EPS CSP

Research Scholar - Adil Ahmad

Supervisor - Prof. Yogendra Singh

In this study, strength and seismic safety of Expanded Polystyrene (EPS) core sandwich panel wall is determined under in-plane cyclic load test. The wall panels were constructed by concrete wythes with welded wire mesh joined by shear connectors and EPS core. The micro concrete was sprayed on EPS panel on both sides of required thickness. This structural system is environment friendly and have various advantages over conventional construction methods, such as speedy construction, cost effective, energy efficient, light weight, avoiding shuttering and heavy machinery, thermal, sound and moisture resistant. Ideal for mass housing projects.