Design and Analysis of Inflatable Military Decoys & Testing of Experimental model.

Sponsor: DRDO-Pune

Prof. Sanjay H Upadhyay

Deployment Mechanisms for 12m Diameter Spacecraft Antennas.

Sponsor: Indian Space Research Organizations (ISRO), Bengaluru (Govt. of India)

Prof. Sanjay H Upadhyay

Design And Development Of A Proof-Of-Concept Model Of A Packaging Methodology For Gossamer Space Antenna Structures.

Sponsor: Space Application Centre (SAC), Indian Space Research Organizations (ISRO)SAC-ISRO(Govt. of India)

Project Outlay: Rs. 26,20,000/- (26.20 Lac)

Prof. Sanjay H Upadhyay

Abstract

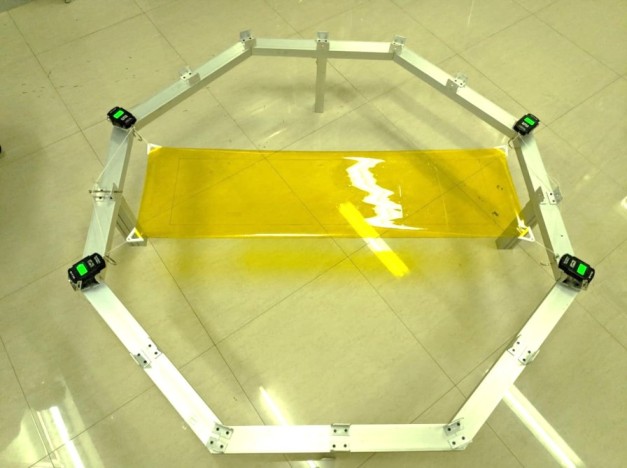

The project focuses on the development of a proof-of-concept model of a planer and parabolic membrane reflector antenna. The research work mainly includes the mechanical design of the inflatable antenna design technology. It is required to investigate different types of folding techniques and design a suitable folding method for planer and parabolic antenna assembly.

The other major research problem is to analyze different rigidization techniques for inflatable membrane structures. The antenna assembly needs to be rigidized after the removal of internal gas pressure to maintain its structural properties.

Dynamic Modeling and Simulations of Human Body Subjected to Mechanical Loads During Spaceflight and Operations in Space.

Sponsor: VSSC-ISRO (Co-PI)

Prof. Sanjay H Upadhyay

Dynamic Analysis And Shape Control Of Inflatable Structures For Space Applications.

Sponsor: INDO-SRI LANKAN JOINT RESEARCH PROJECT Ministry of Science and Technology, Department of Science and Technology (International Bilateral Cooperation Division)

Project Outlay: Rs. 48,91,568/- (48.91 Lacs)

Prof. Sanjay H Upadhyay

Abstract

This project deals with the development of inflatable technology applicable to large, lightweight structures and apertures. Areas of specific interest are Inflatable structure with minimum surface error for shape control of large membrane mirrors and antennas, fold line behavior in membrane reflector, methods to minimize RMS surface error, wrinkle-free design of tensioned membrane, controlling structural geometry and dynamics. This research will provide valuable knowledge regarding the complex dynamics of such structures to improve their precision considerably.

Results and the skills gained by the personnel involved will be in demand by the space industry and organizations related to aerospace systems. Also, the long-term effects of this research will be beneficial to any engineering application consisting of hybrid structures (solid/cable elements). Research data for Kapton and Mylar membranes will also impact other engineering fields such as MEMS technology and electronic devices.

Design & Development Of A Proof-Of-Concept Model Of An Adaptive Membrane.

Sponsor: Space Application Centre (SAC), Indian Space Research Organizations (ISRO)SAC-ISRO(Govt. of India)

Project Outlay: Rs. 29,75,000/- (29.75 Lac)

Prof. Sanjay H Upadhyay

Abstract

The objective of this research is to understand the behavior of an Adaptive membrane model using geometric and material performance, considering orbital and launch conditions. The effects of the physical characteristics like the pre-stress, launch and orbital loads, etc. help to understand the non-linear analysis in terms of other details of dynamic characteristics of mode shape and the natural frequency.

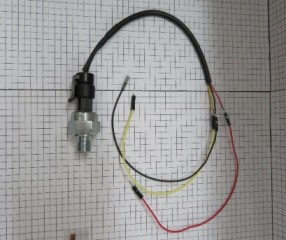

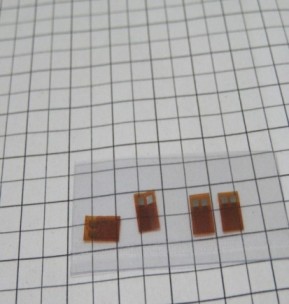

Wrinkle & creases effect on surface-RMS, distribution of shape error across the surface, the effect of piezo-patches on the dynamics & shape of the membrane model, and the orientation(s) of the patches, etc. helps in robust design of space antenna in orbital and launch conditions.

Residual Life Prediction and Vibration Analysis of a High-Speed Rotor Bearing System.

Sponsor: AERONAUTICS R&D BOARD, DRDO (Govt. of India)

Prof. Sanjay H Upadhyay

Health Diagnosis of high-Speed Ball Bearing using Acoustics Emission Techniques.

Sponsor: MHRD- Indian Institute of Technology Roorkee (IITR)

Prof. Sanjay H Upadhyay

1. "3 Phase Asynchronous Traction Motor - Design Analysis" - funded by TWL

2. "Traction Motor Mechanical - FEA" funded by TWL.

3. "Vetting of Spherical Bearing Design" funded by PNC INFRATECH Ltd.

4. "Design Vetting of EOT Crane" funded by RCC Infra Ventures Ltd.

5. “Design of a suitable Tilting Pad Thrust bearing for a VRM Gearbox” funded by Premium Transmission Ltd.

6. " Performance Enhancement of Multipurpose High-Low Pressure Fire Pump“ funded by Shri Ganesh Fire Equipment (P) Ltd.

7. "Analysis for the Ball Mill Shaft” funded by Electro Magnetic Industries

8. “Balancing of rotor” funded by Micro Engineer Ltd.

9. “Balancing of agitator” funded by Gayatri Mineral Technologies Pvt. Ltd.

10. “Design modification of agitator” funded by Indian Petrochemicals Corporation Limited

11. "Vibration measurement” funded by Gujarat State Fertilizer & Chemicals Limited, India

12. “Bearing failure analysis of electric motor” funded by Elecon Engineering Company Limited (Gear Division)

.jpg)